Your favourite Genoa salami do not just magically appear on the charcuterie board. It's gone through meat curing process in a meat chamber done by people who surely know what they are doing. But you not need always buy when you can make also it yourself, right?

Quality meat, nitrites & nitrates, and hygienic environment are three of the most important factors for dry curing in a curing chamber. Aside from those just mentioned, temperature and humidity are the elements that must be looked at carefully

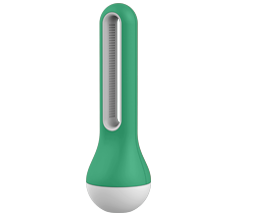

For dry cured salami (after fermentation), temperature must be within 10-16°C range. As for the humidity, it must be within 60-80%. Airflow and moisture consistency in the environment is the key to a successful dry curing process. Using AirComfort during the process of curing meat can help you properly monitor the climate inside your curing chamber.

On the App, you can set the min-max of both temperature and humidity values. If you see that it’s dipping down the proper range, then, you can adjust your fan for example. With AirComfort monitoring your curing chamber, you have more control of the meat curing process.

Get your own AirComfort here.

Happy curing!